Driving Heavy Equipment Efficiency with Hydraulic Steering Systems

How does a hydraulic steering unit work?

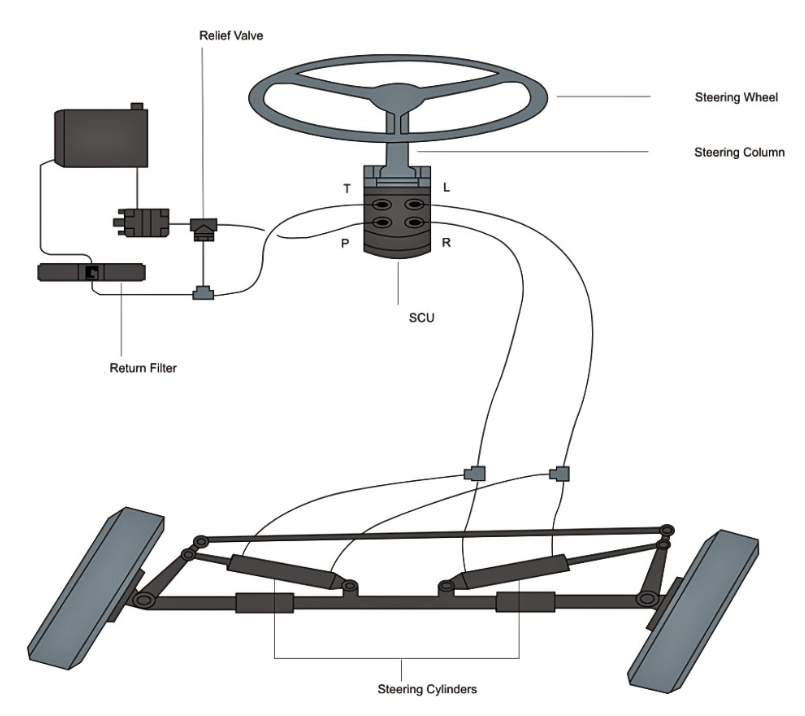

A steering control unit (SCU)—often called an orbitrol or hydrostatic steering unit—is a core component in many off-road and mobile machines like tractors, loaders, and forklifts. It enables smooth, precise, and low-effort steering by using hydraulic power instead of mechanical linkages.

The hydraulic steering control unit is composed of a rotary valve and a rotary meter. It connects to the vehicle’s steering wheel via a steering column. When the steering wheel is turned, hydraulic oil is directed from the system’s pump through the rotary valve and meter to either port L or R, depending on the direction of rotation.

The rotary meter delivers oil to the steering cylinder in proportion to the angular movement of the steering wheel, ensuring precise and responsive steering control.

What’s the difference between open-center and closed-center steering units?

The difference between open-center and closed-center steering units lies in how hydraulic fluid flows through the system when the steering is not being used, and how the hydraulic circuit is configured. These systems are common in hydrostatic steering used in tractors, construction equipment, and other off-road vehicles.

Comparison between Open Center or Closed Center Steering Units

| Feature | Open-Center System | Closed-Center System |

|---|---|---|

| Flow at rest | Constant flow | No flow |

| Pump type | Fixed displacement | Variable displacement or load-sensing |

| Efficiency | Lower | Higher |

| Complexity | Simpler | More complex |

| Multi-function support | Limited | Excellent |

| Typical use | Basic equipment, lower cost | Advanced machinery, high-performance |

Do hydraulic steering units require external power?

Hydraulic steering units do not require external electrical power to function — instead, they rely on hydraulic power, typically supplied by an engine-driven pump.

Power Source:

-

Powered by pressurized hydraulic fluid from a pump.

-

The pump is usually mechanically driven by the vehicle’s engine (via belt, gear, or shaft).

No External Electrical Power Required:

-

These systems are purely hydraulic.

-

The steering unit (orbitrol) directs fluid to steering cylinders based on the rotation of the steering wheel.

-

Manual fallback: Many designs offer limited manual steering if pump pressure is lost, using built-in mechanical reaction or hand-pump action from the orbitrol.

Can hydraulic steering units provide feedback to the steering wheel?

Hydraulic feedback is the reactive force felt by the operator due to pressure changes in the hydraulic circuit. It improves control, handling, and safety — but is not always present, depending on system design.

| Steering Unit Type | Feedback to Steering Wheel? | Steering Feel | Self-Centering |

|---|---|---|---|

| No Reaction | ❌ None | Disconnected | No (unless geometry forces it) |

| Reaction / Load-Reactive | ✅ Yes | Natural feel | Yes (when load acts to center) |

Rule of Thumb:

- If your steering unit is labelled "Non-Reaction" or "No Reaction", it will not provide feedback.

- If you want feedback, ask for a “reaction” or “load-reactive” steering unit.

Which steering unit is right for my machine?

Choosing the right steering unit for your machine depends on several key factors related to the machine's application, hydraulic system, and operating environment. Here’s a detailed breakdown to help guide your decision:

1. Machine Type and Application

| Machine Type | Common Steering Unit Requirement |

|---|---|

| Tractors / Ag Vehicles | Load-sensing, reaction or non-reaction units |

| Forklifts / Telehandlers | Compact, low-displacement, often non-reaction |

| Construction Equipment | Robust, high-displacement, reaction units |

| Utility Vehicles / ATVs | Lightweight, responsive, usually non-reaction |

| Road Vehicles | Precision steering, often closed center with feedback |

2. Hydraulic System Type - The steering unit must be compatible with your hydraulic setup.

- Open Center: Constant flow; simple systems. Most commonly used in light and medium-duty machines.

- Closed Center: Flow is on-demand; used in more sophisticated, load-sensing systems.

- Load-Sensing: Efficient systems that adjust flow/pressure based on steering demand.

3. Reaction vs Non-Reaction - This refers to whether road surface feedback is transferred back to the steering wheel.

- Reaction Units: Allow feedback from the wheels to the steering wheel, useful for operators who need road feel or manual override, Common in construction and road vehicles

- Non-Reaction Units: Isolate the steering wheel from feedback, Prevents kickback or movement of the wheel when not turned by the operator, Ideal for off-road and agricultural use

4. Displacement (cc/rev)

This determines how much fluid is moved per turn of the steering wheel

Choose based on how quickly and how much force your machine needs to turn the wheels.

5. Mounting and Port Configuration

Are hydraulic steering systems suitable for high-speed vehicles?

Hydraulic steering systems are not naturally suited to high-speed vehicles due to their lack of road feel, slower responsiveness, and potential safety risks. However, with advanced designs and fail-safes, they can be engineered to work in some high-speed specialty applications—but they're usually not the best choice for modern high-speed vehicles.

Hydraulic steering is commonly used in specialized vehicles such as military transports, heavy-duty trucks, airport fire engines, and off-road racing vehicles (e.g., rally trucks). In these applications, the systems are enhanced with features like reaction-type steering valves for improved driver feedback, closed-center load-sensing hydraulics to ensure responsive control, and redundant mechanisms such as backup pumps or mechanical overrides to maintain safety and reliability.

What information do I need to order a replacement steering unit?

To order a replacement steering unit, you'll need to gather specific technical and application details to ensure compatibility and proper performance. Below is a comprehensive checklist of the key information required:

| Category | Details |

|---|---|

| Identification | Model, serial number, manufacturer |

| Specs | Displacement, reaction type, center type, porting |

| Mounting | Bolt pattern, flange, shaft type |

| Application | Machine model, usage environment |

| System Info | Pressure, flow, pump type |

Do hydraulic steering units come with built-in load sensing or priority valves?

Yes, some hydraulic steering units do come with built-in load sensing and/or priority valves, especially in modern or OEM-focused systems. However, not all units include these, so it's essential to review the specific model details or system requirements before ordering or designing the hydraulic layout.

Steering Unit Alternatives & Equivalents

Find the perfect match: our steering units are cross-compatible with major brand models, built for easy interchangeability, trusted durability, and at a much more competitive price.

| BPB1 | BPB2 | BPB3 | BPB5 | BPBS1 | BPBS2 | BPBS5 | BPBS5T | VLSA | (D) YXL | |

|---|---|---|---|---|---|---|---|---|---|---|

| DANFOSS | OSPB ON | OSPB OR | OSPB CN | OSPB LS (OLS) | OSPC ON | OSPC OR | OSPC LS (OLSA) | OSPC LS (OLS) | OLSA | OLS |

| M+S | HKU…/4 | HKU…/3 | HKU…/7 | HKU…/5T | HKUS…/4 | HKUS…/3 | HKUS…/5D | HKUS…/5DT | PRD (D) | PRT |

Why Buy Hydraulics from Flowfit?

- Premium Quality: We supply hydraulic steering units made from top-grade materials, ensuring long-lasting durability and exceptional performance in even the most demanding applications.

- Comprehensive Range: We offer a comprehensive range of agricultural hydraulic components—including pumps, valves, cylinders, hoses, fittings, and fluid control systems

- Customisable Solutions: Flowfit provides tailored power units that meet the unique specifications of your equipment and industry.

- Free UK Shipping: We offer free UK shipping on orders over £250, making it easier and more affordable to get the hydraulic components you need delivered straight to your door.

- Global Shipping: Flowfit proudly serves customers across the UK and worldwide, ensuring that top-quality hydraulic products are available no matter where you are.

Browse our selection of hydraulic steering units and find the ideal hydraulic solution for your needs. Our team of hydraulic specialists are ready to assist you with expert advice and help you find the best products for your equipment.

For more information, get in touch with our team of hydraulic specialists today

The total one-stop supplier for hydraulic components & systems

Get in touch

Parys Road

Ludlow

Shropshire

SY8 1XY