What Is A Hydraulic Press, And How Are They Used?

What is a hydraulic press?

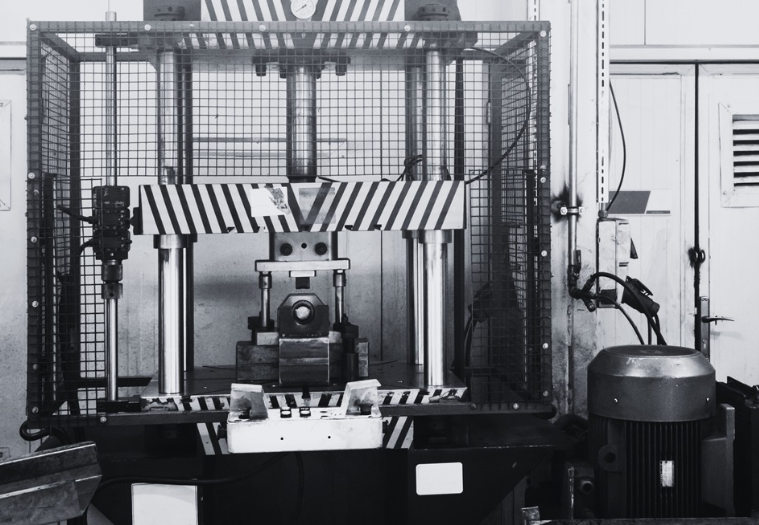

A hydraulic press is a machine with a bed or plate where an item—often metal—is placed to be crushed, straightened, or moulded. It operates on Pascal’s Law, which states that pressure applied in a confined fluid remains constant throughout the system.

By using hydraulic cylinders and motors, the press multiplies force, making it a powerful tool for metal forming, compression, and shaping materials across industrial, automotive, and recycling applications.

How Does A Hydraulic Press Work?

The workings of a hydraulic press are very similar to a standard hydraulic system. It uses the same core components: hydraulic motors, cylinders, pistons, and pipes. The principle behind it is Pascal’s Law, which states that pressure applied to a confined fluid is transmitted equally throughout the system.

Step-by-Step Process

-

Two-Cylinder System – A press contains a small cylinder (slave cylinder) and a large cylinder (master cylinder), both connected by a pipe.

-

Fluid Compression – Hydraulic fluid is poured into the small cylinder. When its piston is pushed, the fluid is compressed.

-

Pressure Transfer – The compressed fluid flows through the connecting pipe into the larger master cylinder.

-

Force Amplification – The master cylinder’s larger piston pushes the fluid back into the slave cylinder, multiplying the force and creating powerful output.

-

Material Shaping – This amplified force is applied to the press bed or plate, allowing the machine to crush, straighten, mould, or shape materials.

What Are The Uses Of A Hydraulic Press?

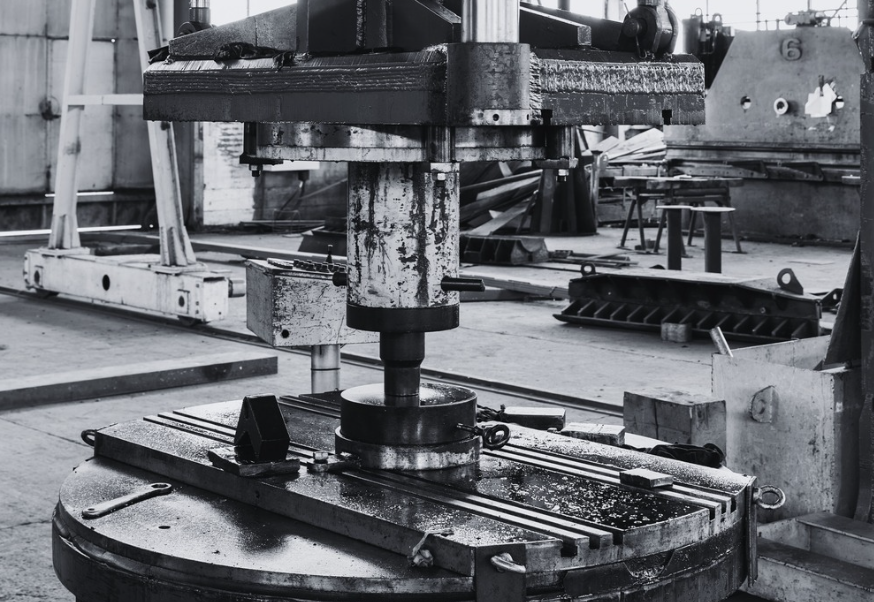

A hydraulic press works by applying force on fluids through a hydraulic motor and slave cylinder, which is then amplified in the master cylinder. This process generates immense pressure, making the hydraulic press ideal for industrial applications where high force is needed to compress or shape materials.

Industrial & Manufacturing

-

Metal forming – transforms metallic objects into sheets of metal

-

Glass industry – used to thin glass for precision products

-

Cosmetics & pharmaceuticals – compresses powders to create makeup products and medical tablets

-

Blacksmithing & forging – modern blacksmiths use presses for shaping strong, consistent parts

Automotive & Junkyard Applications

-

Car crushing – the hydraulic press is the heart of junkyard systems, where extreme force drives plates onto vehicles to crush them into compact units

-

Automotive repairs – installing bearings, straightening bent components, and forming metal parts

Recycling & Waste Management

-

Scrap compression – compresses scrap metal, plastics, and paper into dense, manageable bales

-

Waste reduction – crushes bulky items for easier handling and transport

Food & Specialty Uses

-

Cocoa powder production – creates fat-free cocoa by pressing out excess butter

-

Specialized powders – for various industrial and consumer products

High-Performing Hydraulics For Your Hydraulic Press, From Flowfit

Hydraulic presses are powerful, versatile machines used across industries — from metal forming and automotive repair to recycling, food, and cosmetics. Their ability to generate immense force makes them an essential tool for both workshops and large-scale manufacturing.

At Flowfit, we don’t just supply hydraulic components — we provide expert advice, reliable parts, and industry-leading service. Whether you need hydraulic motors, cylinders, or replacement parts, we ensure you get the right solution at the right price.

Ready to upgrade your setup with a reliable hydraulic press or hydraulic components?

Shop Hydraulic Solutions at Flowfit Today

The total one-stop supplier for hydraulic components & systems

Get in touch

Parys Road

Ludlow

Shropshire

SY8 1XY