Tiny but Mighty: Why Hydraulic Adaptors Deserve Your Attention

What is a hydraulic adaptor?

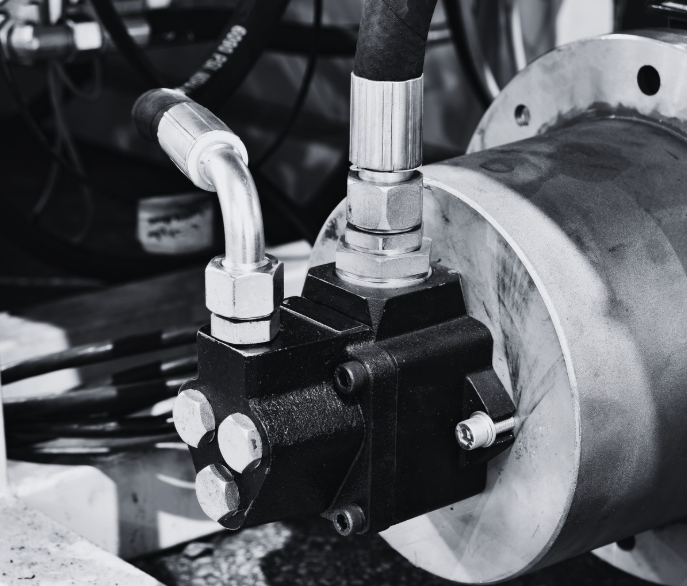

A hydraulic adaptor also known as a hydraulic connector is a specialized fitting used to connect different components in a hydraulic system, especially when those components have incompatible thread types, sizes, or connection styles. Adaptors serve as the essential link between hydraulic hoses, pipes, pumps, cylinders, and other elements, allowing fluid to flow seamlessly and safely through the system.

What does an adaptor fitting do?

A hydraulic adaptor fitting serves a critical role in connecting two or more hydraulic components that otherwise wouldn't fit together due to differences in thread type, size, or connection format. Think of it as a translator between parts—it makes mismatched components compatible within a hydraulic system.

When should you use a hydraulic adaptor in a fluid power system?

A hydraulic adaptor becomes essential in a fluid power system whenever there’s a need to bridge mismatched components, customize connections, or enhance flexibility. These fittings help you create safe, sealed connections when your components differ in size, thread type, or orientation—and can save you from costly equipment replacements or major redesigns.

How does a hydraulic adaptor differ from a hydraulic fitting?

| Feature | Hydraulic Adaptor | Hydraulic Fitting |

|---|---|---|

| Primary Function | Connects incompatible components | Joins compatible components within the system |

| Thread Type Matching | Often used to change or bridge thread types | Designed to connect components with matching threads |

| Size Transition | Often used to transition between different sizes | Typically used for same-size connections |

| Connection Role | Acts as a conversion interface | Forms a permanent or semi-permanent system connection |

| Flow Direction Options | Includes elbows, tees, bulkheads for layout flexibility | Usually straight or pre-defined shapes |

| Use Case | Solves mismatch issues in retrofits, repairs, upgrades | Standard in new system installations |

What materials are commonly used in hydraulic adaptors and why?

Hydraulic adaptors are commonly made from:

-

Carbon steel – For strength and general-purpose use

-

Stainless steel – For corrosion resistance in harsh environments

-

Brass – For lower-pressure or more chemically sensitive systems

Are stainless steel hydraulic adaptors better than brass or carbon steel ones?

It depends on your application. Stainless steel hydraulic adaptors are superior in some ways, but not always the best choice across the board. Each material—stainless steel, brass, and carbon steel—has strengths and trade-offs based on performance needs, cost, and environmental conditions.

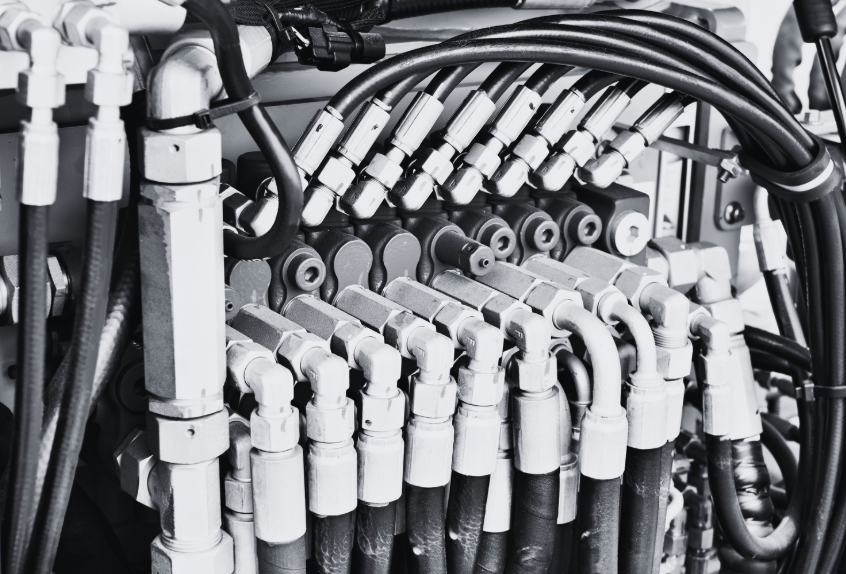

How do you choose the right hydraulic adaptor for your application?

Choosing the right hydraulic adaptor means understanding your system’s specs, fluid, environment, and connection needs. Take the time to check every variable—compatibility and safety depend on it.

Key things to think about:

- What thread types am I connecting?

- What are the fitting sizes and connection styles?

- What is my system’s max pressure and fluid type?

- What material suits the environment?

- Do I need elbows, tees, or special shapes?

- What sealing method is best for my system?

🔧 Tip: Use a thread identification kit or chart to confirm male/female threads, pitch, and thread angle.

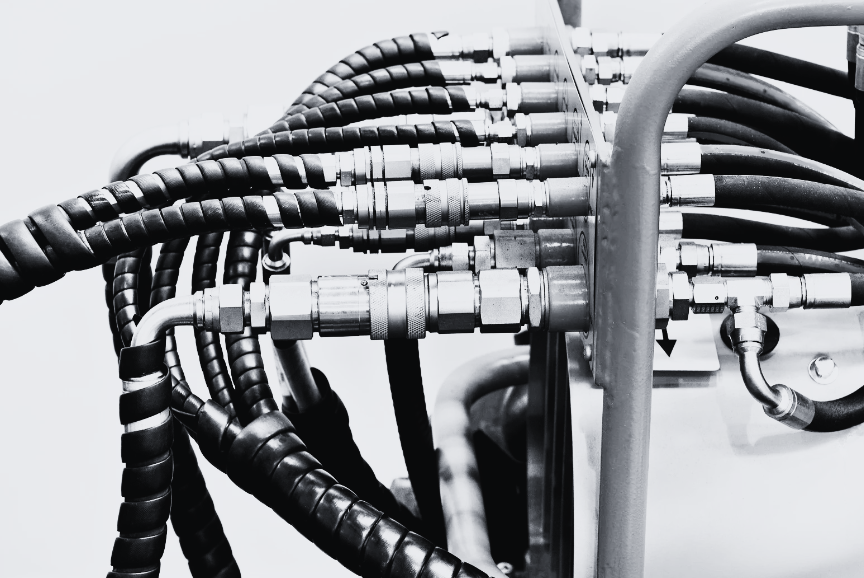

How do you identify thread types on a hydraulic adaptor?

Correctly identifying the thread type on a hydraulic adaptor is essential to ensure leak-free connections, avoid costly downtime, and prevent system damage. With numerous global standards in use—NPT, BSP, JIC, SAE, ORFS, Metric, and more—knowing how to distinguish them is a key skill in fluid power systems.

🔧 Thread standards can look very similar—especially BSPT vs NPT or JIC vs SAE. Always measure both thread size and pitch, and inspect the seal style to be certain.

| Thread Standard | Tapered? | Seal Style | Use |

|---|---|---|---|

| NPT/NPTF | Yes | Thread interference | U.S. hydraulic systems |

| BSPT | Yes | Thread + sealant | UK/Asia systems |

| BSPP | No | Washer or Bonded seal | UK/European hydraulics |

| JIC | No | 37° flare metal seal | Global, high-pressure systems |

| SAE 45° | No | 45° flare metal seal | Automotive, light-duty |

| ORFS | No | O-ring face | Leak-free, high-pressure |

| Metric DIN | No | 24° cone or O-ring | European equipment |

How do you install a hydraulic adaptor correctly?

Correct installation = leak prevention, safety, and long service life.

Summary Checklist

- Identify correct thread type and seal method

- Clean threads thoroughly

- Use sealant only when needed

- Hand-tighten, then torque to spec

- Check alignment and test under pressure

🛠️ Safety Tips:

What are common problems caused by a faulty hydraulic adaptor?

A faulty hydraulic adaptor—whether poorly manufactured, incorrectly installed, or simply worn out—can be the weakest link in your fluid power system. Even though adaptors are small components, they play a crucial role in maintaining system integrity, pressure, and safety.

Here are the most common problems a faulty hydraulic adaptor can cause:

A faulty hydraulic adaptor can cause anything from a small leak to a system-wide shutdown. Proper selection, installation, and maintenance are key to preventing problems.

Can a hydraulic adaptor help prevent system leaks?

Yes — when selected and installed correctly, a hydraulic adaptor can absolutely help prevent system leaks. In fact, adaptors are often essential for creating secure, leak-free connections between mismatched or incompatible components in hydraulic systems.

However, it's important to understand that an adaptor can either prevent or cause leaks, depending on the quality, compatibility, and installation of the component.

Is it safe to reuse a hydraulic adaptor in a new installation?

Sometimes — but with caution. Reusing a hydraulic adaptor can be safe in non-critical, low-pressure applications if it has been thoroughly inspected and tested. However, in high-pressure or safety-sensitive environments, it’s usually not recommended due to the risks of wear, thread damage, and seal failure.

Why Buy Hydraulic Adaptors from Flowfit?

- Premium Quality: Flowfit’s hydraulic adaptors are made from top-grade materials, ensuring long-lasting durability and exceptional performance in even the most demanding applications.

- Comprehensive Range: We offer a wide selection of types and sizes to suit your specification.

- Customisable Solutions: Flowfit provides tailored power units that meet the unique specifications of your equipment and industry.

- Free UK Shipping: We offer free UK shipping on orders over £250, making it easier and more affordable to get the hydraulic components you need delivered straight to your door.

- Global Shipping: Flowfit proudly serves customers across the UK and worldwide, ensuring that top-quality hydraulic products are available no matter where you are.

Browse our selection of hydraulic adaptors and find the ideal hydraulic solution for your needs. Our team of hydraulic specialists are ready to assist you with expert advice and help you find the best products for your equipment.

For more information, get in touch with our team of hydraulic specialists today!

The total one-stop supplier for hydraulic components & systems

Get in touch

Parys Road

Ludlow

Shropshire

SY8 1XY