Tank Smarter, Not Heavier: The Aluminium Revolution in Hydraulics

Why choose aluminium over steel or plastic for hydraulic tanks?

Choosing aluminium over steel or plastic for hydraulic tanks offers a well-rounded set of advantages that balance performance, durability, and efficiency. Here's a detailed breakdown of why aluminium is often the material of choice:

- Weight Advantage: Aluminium is significantly lighter than steel—up to 60% lighter for the same volume. This weight reduction is especially beneficial in mobile hydraulic applications like trucks, trailers, and construction equipment, improving fuel efficiency and payload capacity.

- Corrosion Resistance: Aluminium has natural corrosion resistance due to its oxide layer, making it ideal for outdoor or humid environments. Unlike steel, aluminium does not require painting or coating to resist rust—though anodizing or powder coating may still be added for durability and aesthetics.

- Better Heat Dissipation: Aluminium has excellent thermal conductivity, allowing it to dissipate heat from hydraulic fluids more efficiently than steel or plastic. This helps maintain fluid performance and viscosity, especially in high-temperature or high-duty-cycle systems.

- Structural Integrity and Strength-to-Weight Ratio: Though not as strong as steel pound-for-pound, aluminium offers a high strength-to-weight ratio, making it suitable for most low-pressure reservoir applications. When engineered with reinforced designs and internal baffles, aluminium tanks maintain structural integrity under vibration and fluid surge.

- Recyclability and Sustainability: Aluminium is 100% recyclable without degradation, offering a greener lifecycle than many plastic-based tanks.

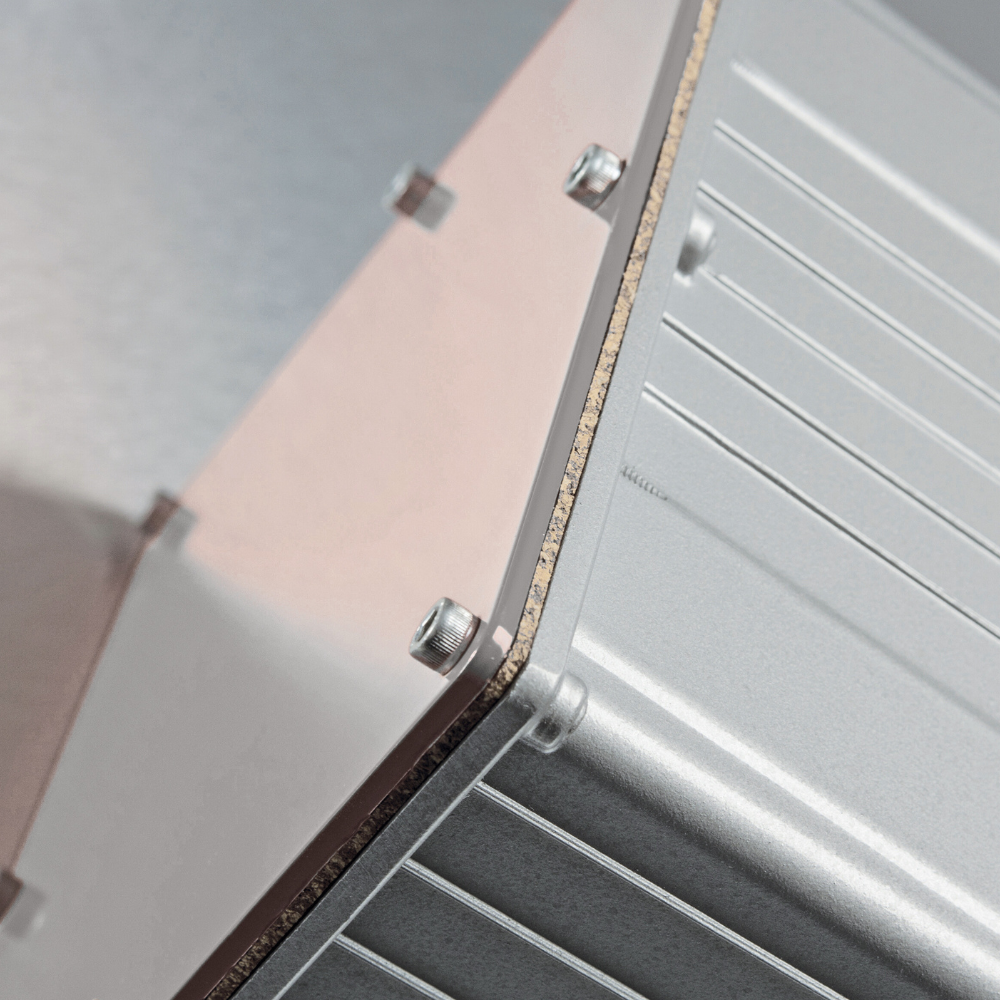

- Customization & Machinability: Aluminium is easier to fabricate and machine than steel, which allows for custom port placements, integrated fittings, flexible shapes and sizes. This makes it attractive for OEMs or custom machinery builders.

Is aluminium strong enough for rugged hydraulic applications?

Yes—aluminium is rugged enough for most hydraulic tank applications when the right alloy, design, and protective features are in place. It delivers strength, durability, and efficiency without the weight and rust risks of steel.

⚙️ Applications Where Aluminium Performs Well

-

Utility vehicles and service trucks

-

Construction machinery (e.g., skid steers, backhoes)

-

Agricultural sprayers and tractors

-

Forestry and mining support equipment

-

Industrial power units with moderate operating demands

Are aluminium tanks compatible with all hydraulic oils, including bio-based fluids?

Yes—aluminium tanks are generally compatible with both standard and bio-based hydraulic fluids, provided the fluids are well-formulated and system maintenance is consistent. For maximum longevity, verify chemical compatibility and keep the tank well-ventilated and clean.

🔧 Preventive Measures

To ensure safe long-term use with aluminium tanks:

-

Use a desiccant breather to reduce moisture ingress.

-

Ensure regular fluid testing and replacement to avoid acid build-up.

-

Choose anodized or internally coated tanks if long-term fluid compatibility is a concern.

-

Consult both the tank and fluid manufacturer for a compatibility matrix if using specialty or eco-friendly fluids.

How do aluminium tanks handle thermal expansion or pressure changes?

Aluminium tanks manage thermal expansion well due to their high conductivity and predictable expansion. Pressure changes are safely handled via proper venting and non-pressurized design assumptions. Issues only arise when breather systems fail or pressure loads exceed the tank’s intended design.

How do aluminium tanks perform in extreme environments (cold, humid, coastal)?

Aluminium tanks excel in cold, humid, and coastal environments, offering rust resistance, durability, and thermal advantages. For the harshest settings, surface treatments and marine-grade alloys are recommended to maximize service life.

⚠️ Tip: Ensure tank heaters are used in extremely cold environments to prevent fluid thickening or tank icing.

What is the pressure rating for the tank (if used in pressurized systems)?

Standard aluminium hydraulic tanks are atmospheric and rated for very low pressure (< 5 psi). If pressure is required, you must use a specially engineered pressure-rated tank with proper certification.

How often do aluminium tanks need to be inspected or serviced?

Inspect aluminium tanks monthly, clean quarterly, and conduct internal inspections every 6–12 months. Adjust frequency based on environment and system duty cycle. Routine care prevents leaks, contamination, and early corrosion—especially with bio-fluids or high-use systems.

🔧 Other Service Intervals

| Component | Recommended Service Interval |

|---|---|

| Breather Filter | Every 3–6 months (or as needed) |

| Return Filter | Every 6 months or 500 hours |

| Desiccant Breather | Replace when colour changes or saturated |

| Tank Interior Cleaning | Every 1–2 years (or during fluid replacement) |

| Sight Glass Replacement | As needed (check for clouding or cracks) |

Do aluminium tanks corrode or oxidize over time?

Aluminium tanks naturally oxidize but rarely corrode under normal conditions. With basic design precautions and periodic maintenance, aluminium remains one of the most corrosion-resistant and low-maintenance materials for hydraulic tanks.

🧪 Signs of Oxidation or Corrosion

| Condition | Likely Cause | Action Needed |

|---|---|---|

| White powdery film | Normal oxidation | No action – protective layer |

| Greyish discoloration | Moisture or condensation | Improve ventilation, clean tank |

| Pitting or bubbling | Salt, chemicals, dissimilar metals | Inspect, neutralize, consider coating |

| Flaking or deep corrosion | Severe chemical attack | Replace or repair as needed |

What’s the expected service life of an aluminium hydraulic tank?

A well-designed and maintained aluminium hydraulic tank can reliably last 15–25 years, even in moderately demanding environments. In mobile or marine applications, with coatings and regular upkeep, 10–20 years is typical.

What accessories are beneficial for aluminium hydraulic tanks?

For optimal performance, an aluminium hydraulic tank benefits from integrated oil sump features, vibration-dampened mounting feet, and a combination of filtration, ventilation, and monitoring accessories. These not only extend tank life but also improve system reliability and fluid cleanliness.

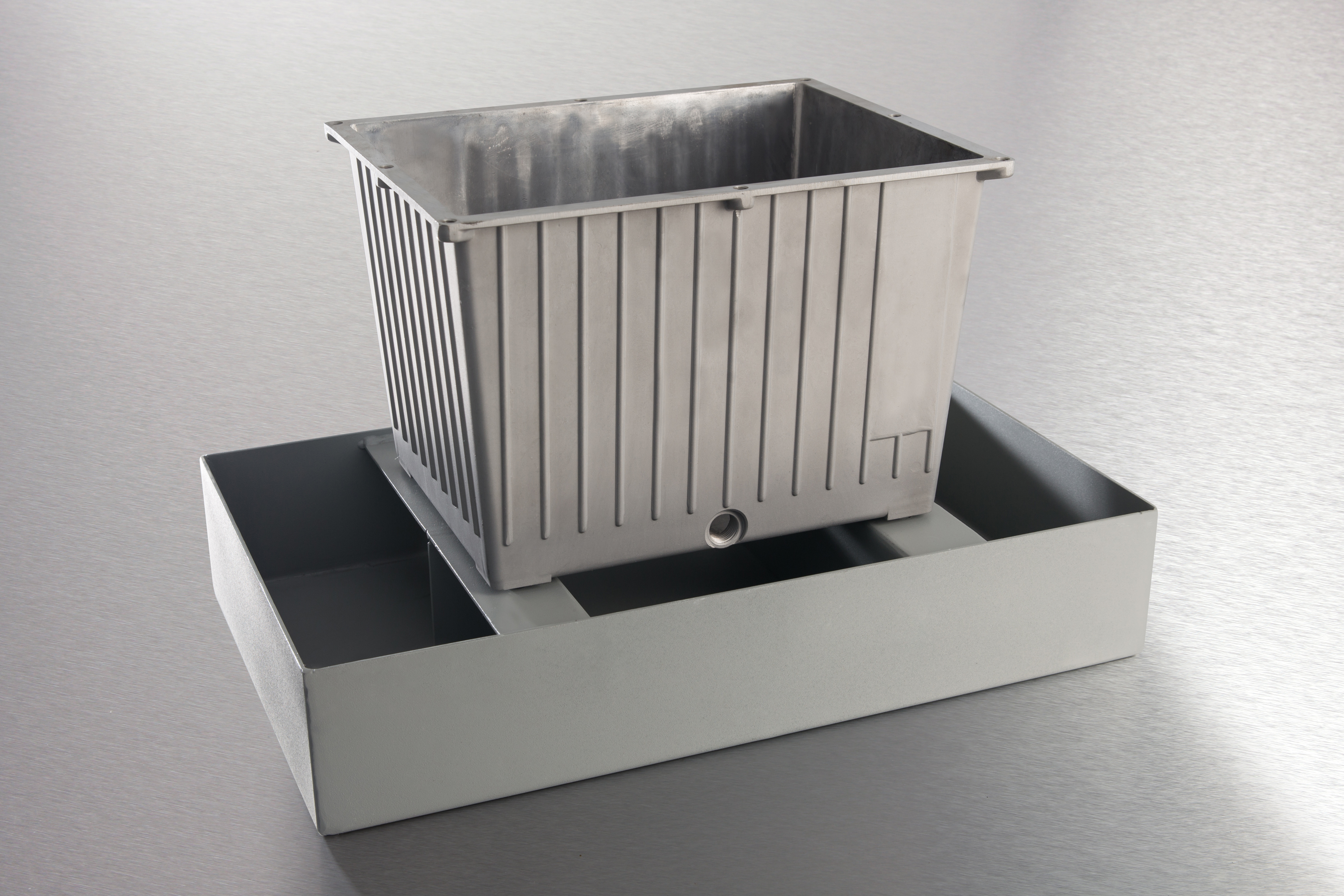

1. Oil Sump

-

Purpose: The sump serves as a holding tank for hydraulic oil when it is not in active circulation.

-

Benefits: Heavier particles and debris in the oil can settle at the bottom of the sump, helping protect the rest of the system.

- Purpose: Secure installation and vibration protection.

- Benefits: Allows flexible tank positioning (side, base, upright) and prevents weld fatigue.

3. Additional Key Accessories

| Accessory | Function / Benefit |

|---|---|

| Breather Cap / Desiccant Breather | Allows airflow while blocking dust and moisture. |

| Return Line Filter | Removes contaminants from return oil before entering the tank. |

| Magnetic Drain Plug | Collects ferrous debris from oil; easy to clean during draining. |

| Sight Gauge with Thermometer | Monitors fluid level and temperature simultaneously. |

| Suction Strainer | Prevents large particles from entering the pump inlet. |

| Filler Strainer Basket | Stops debris during oil fill-ups. |

| Tank Heater (Pad or Immersion) | Keeps fluid at optimal viscosity in cold climates. |

| Overflow Catch Can | Captures overflow oil, especially in mobile applications. |

Why Buy Hydraulic Aluminium Tanks from Flowfit?

- Premium Quality: Flowfit’s aluminium tanks are made from top-grade materials, ensuring long-lasting durability and exceptional performance in even the most demanding applications.

- Comprehensive Range: We offer a wide selection of capacity of tank sizes to suit your specification.

- Customisable Solutions: Flowfit provides tailored power units that meet the unique specifications of your equipment and industry.

- Free UK Shipping: We offer free UK shipping on orders over £250, making it easier and more affordable to get the hydraulic components you need delivered straight to your door.

- Global Shipping: Flowfit proudly serves customers across the UK and worldwide, ensuring that top-quality hydraulic products are available no matter where you are.

Browse our selection of aluminium tanks and find the ideal hydraulic solution for your needs. Our team of hydraulic specialists are ready to assist you with expert advice and help you find the best products for your equipment.

For more information, get in touch with our team of hydraulic specialists today

The total one-stop supplier for hydraulic components & systems

Get in touch

Parys Road

Ludlow

Shropshire

SY8 1XY