From Field to Function: Understanding Hydraulics in Agriculture

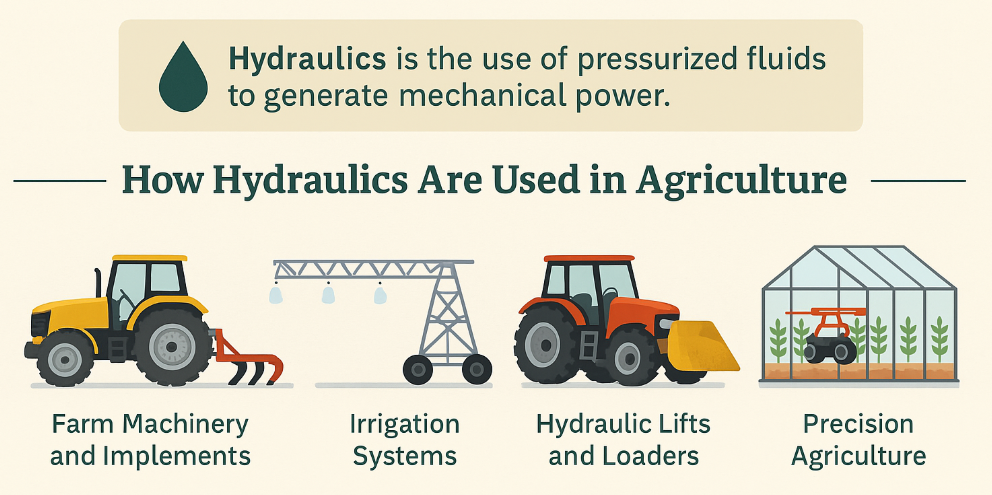

How Are Hydraulics Used in Agriculture?

In agriculture, hydraulics is a foundational technology that powers much of the mechanization and automation we see on modern farms. Here’s how it’s commonly applied:

1. Farm Machinery and Implements

-

Tractors – for power steering, brake systems, and lifting implements (like plows or harrows).

-

Harvesters and Combines – to control headers, conveyors, and unloading augers.

-

Balers, sprayers, and seeders – for compacting, spraying, and distributing materials.

2. Irrigation Systems

-

Pumping stations for moving large volumes of water.

-

Pivot and drip irrigation systems for controlling flow and pressure to distribute water efficiently across large fields.

3. Hydraulic Lifts and Loaders

-

Lifting hay bales, soil, fertilizer, and other heavy farm materials.

-

Controlling front-end loaders or attachments like backhoes and forks.

4. Greenhouse and Barn Automation

-

Ventilation systems (roof and wall openings).

-

Feed delivery systems and manure scrapers.

5. Precision Agriculture

-

Adjusting equipment settings automatically based on GPS and sensor data.

-

Enabling variable rate seeding, fertilization, and spraying.

Why is hydraulic power important for modern farming?

Hydraulic power is critically important for modern farming due to its ability to efficiently drive, control, and automate a wide variety of agricultural tasks.

| Benefit | Description |

|---|---|

| Power & Strength | Handles heavy loads with compact components |

| Precision | Enables fine control for planting, spraying, and harvesting |

| Versatility | Powers many types of equipment |

| Efficiency | Saves time and labour |

| Automation Ready | Integrates with modern ag-tech for smart farming |

What are the main components of a hydraulic system used in farming?

Hydraulic systems are the backbone of modern agricultural machinery, powering everything from lifting heavy loads to steering tractors and operating irrigation systems. Each component—pumps, valves, actuators, fluid, and more—works together to deliver precise, powerful, and reliable performance. Without well-functioning hydraulic components, farming operations would be slower, more labor-intensive, and far less efficient. Properly maintained hydraulics not only boost productivity but also reduce downtime and extend equipment lifespan, making them indispensable on today’s farm.

| Component | Function | Typical Application in Farming |

|---|---|---|

| Hydraulic Pump | Converts mechanical energy into hydraulic pressure by moving fluid | Powers tractor systems, loaders, sprayers |

| Hydraulic Fluid | Transfers power through the system; lubricates and cools components | Circulates in all hydraulic machinery (tractors, balers, etc.) |

| Actuators (Cylinders & Motors) | Converts hydraulic energy into mechanical motion | Raises arms, pushes blades, turns wheels (e.g., in harvesters, loaders) |

| Valves | Control fluid direction, pressure, and flow rate | Enables precision in lifting, steering, spraying |

| Reservoir (Tank) | Stores excess hydraulic fluid, allows for cooling and de-aeration | Ensures steady fluid supply for continuous operation |

| Filters | Removes contaminants from fluid | Protects system from wear, prolongs equipment life |

| Hoses/Tubing | Transports fluid between components | Connects pump, actuators, valves, and tank |

| Coolers | Regulate temperature of hydraulic fluid | Prevents overheating during extended use |

| Seals/Fittings | Prevent leaks, maintain pressure integrity | Found at joints and moving parts of cylinders and hoses |

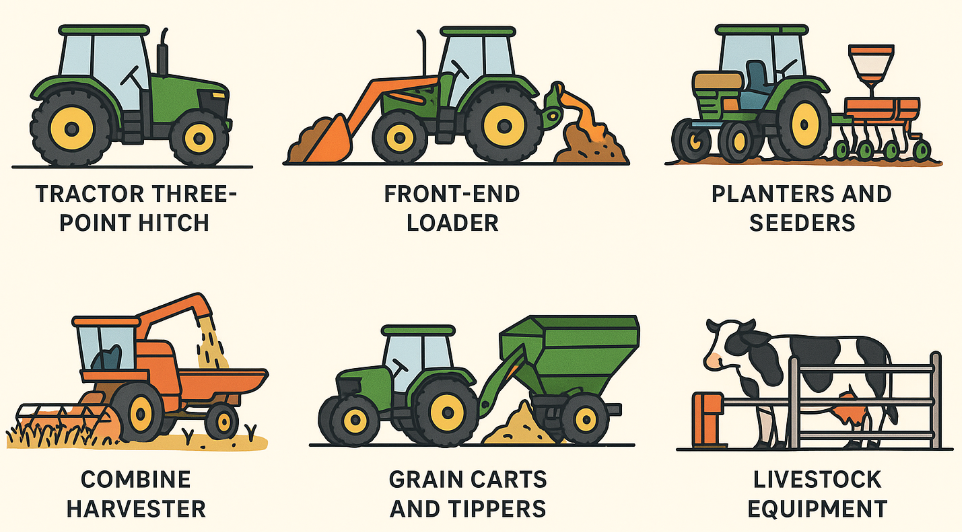

What farming equipment commonly uses hydraulics?

Hydraulic systems are integral to a wide range of farming equipment, powering movement, lifting, steering, and automated control.

| Equipment | Hydraulic Use |

|---|---|

| Tractors | Steering, brakes, loader arms |

| Combine Harvesters | Header & auger controls |

| Balers | Bale chamber, ejection, pickup |

| Plows & Harrows | Blade adjustment and depth control |

| Seeders & Planters | Seed depth, lift systems |

| Sprayers | Boom and spray controls |

| Loaders & Backhoes | Lifting, scooping, digging |

| Mowers | Deck and arm height adjustments |

| Manure/Feed Equipment | Conveyor & gate mechanisms |

| Irrigation Systems | Pumping, pivot, and valve operation |

How do hydraulic systems enhance tractor and harvester performance?

Hydraulic systems play a crucial role in enhancing the performance of tractors and harvesters by enabling powerful, precise, and efficient control over critical operations.

| Function | Hydraulic Benefit | Equipment |

|---|---|---|

| Power Steering | Smooth manoeuvring | Tractors, Harvesters |

| Brake Systems | Safer stopping, especially with heavy loads | Tractors |

| Three-Point Hitch | Easy lifting/adjustment of implements | Tractors |

| Loader/Bucket Operation | Lifting, digging, scooping | Tractors |

| PTO and Transmission | Smooth power flow to tools | Tractors |

| Header/Reel Adjustment | Accurate harvesting height | Harvesters |

| Auger and Grain Tank Control | Efficient unloading | Harvesters |

| Internal Harvesting Mechanism | Crop-specific performance tuning | Harvesters |

How do you maintain hydraulic systems in agricultural machinery?

Maintaining hydraulic systems in agricultural machinery is critical for performance, safety, and equipment lifespan. These systems operate under high pressure and frequent exposure to dust, moisture, and heavy loads—making regular maintenance essential.

🛠️ Quick Tips: Hydraulic Maintenance for Farm Machinery

-

Check fluid level daily; top up with correct hydraulic oil.

-

Inspect for leaks around hoses, seals, and fittings.

-

Replace filters regularly (250–500 hours or sooner in dusty areas).

-

Examine hoses/seals for cracks, wear, or bulging.

-

Monitor pressure & temperature with gauges or thermometers.

-

Bleed the system after fluid changes to remove air.

-

Keep everything clean—wipe ports, cap reservoirs, use sealed containers.

What challenges do farmers face with hydraulic equipment?

Farmers face several practical and technical challenges when using hydraulic equipment in agriculture. While hydraulics offer great power and precision, they require proper handling, regular maintenance, and technical knowledge to prevent costly issues.

| Challenge | Effect on Farm Operations |

|---|---|

| Fluid leaks & contamination | Lower efficiency, increased wear & tear |

| Hose/seal failures | Equipment downtime, safety hazards |

| Overheating | Degraded oil, system shutdowns |

| Difficult diagnostics | Slower repairs, need for expert help |

| Air in system (cavitation) | Jerky movement, pump damage |

| High maintenance demand | Labour/time intensive, risk of neglect |

| Cost of parts | Financial strain, especially for smallholders |

Why Buy Hydraulics from Flowfit?

- Premium Quality: We supply hydraulics made from top-grade materials, ensuring long-lasting durability and exceptional performance in even the most demanding applications.

- Comprehensive Range: We offer a comprehensive range of agricultural hydraulic components—including pumps, valves, cylinders, hoses, fittings, and fluid control systems

- Customisable Solutions: Flowfit provides tailored power units that meet the unique specifications of your equipment and industry.

- Free UK Shipping: We offer free UK shipping on orders over £250, making it easier and more affordable to get the hydraulic components you need delivered straight to your door.

- Global Shipping: Flowfit proudly serves customers across the UK and worldwide, ensuring that top-quality hydraulic products are available no matter where you are.

With decades of experience serving the agricultural industry, Flowfit is your trusted partner for keeping your farm running efficiently, safely, and reliably.

For more information, get in touch with our team of hydraulic specialists today

The total one-stop supplier for hydraulic components & systems

Get in touch

Parys Road

Ludlow

Shropshire

SY8 1XY