Hydraulic Oil Explained: Top 10 Questions Answered

1. What is hydraulic oil and why is it important?

Hydraulic oil is a specially formulated fluid used to transmit power in hydraulic systems. It also lubricates moving parts, protects against wear, reduces heat, and prevents rust or corrosion. Without the right oil, hydraulic machinery can’t run smoothly or reliably.

2. What are the main types of hydraulic oil?

- Mineral-based – the most common, affordable, and widely used.

- Synthetic – engineered for extreme conditions, offering better stability.

- Biodegradable – eco-friendly, used in sensitive environments like agriculture or marine applications.

3. What does ISO VG mean in hydraulic oil (e.g., 32, 46, 68)?

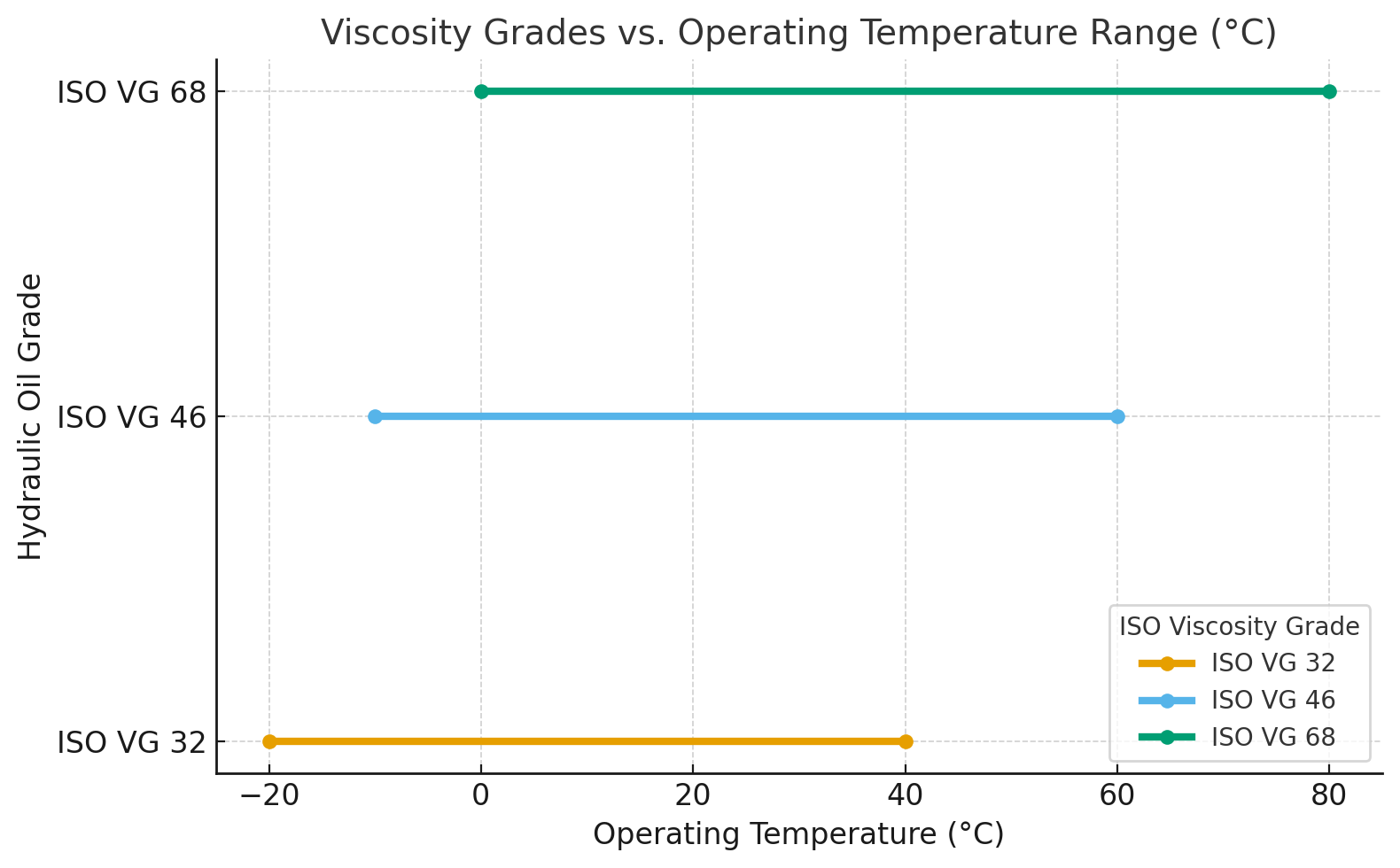

ISO VG (Viscosity Grade) is a measure of the oil’s thickness at 40°C. For example, ISO VG 32 is thinner than VG 68. Choosing the right grade depends on the machine design and the temperature range in which it operates.

4. How do I choose the right hydraulic oil for my equipment?

Choosing the correct hydraulic oil is critical for performance, efficiency, and the lifespan of your equipment. The wrong oil can cause wear, overheating, or even system failure.

1. Follow the manufacturer’s manual: Always start with the recommendations in your machine’s service manual. Manufacturers specify the correct ISO viscosity grade (e.g., VG 32, 46, 68) and whether anti-wear or special additives are required.

2. Match viscosity to operating temperature: In cold environments, use a lower-viscosity oil (e.g., ISO VG 32) for smooth start-up. In hot or heavy-duty operations, higher viscosity (e.g., ISO VG 68) provides better lubrication and film strength.

3. Consider system pressure and duty cycle: High-pressure systems (common in construction or industrial machinery) often require anti-wear (AW) hydraulic oil with zinc or ashless additives to protect moving parts.

👉 Quick tip: If you’re unsure, consult both your manufacturer and your oil supplier — using the right fluid prevents costly breakdowns.

5. What properties should good hydraulic oil have?

Not all hydraulic oils are created equal. The best oils share a set of performance characteristics that keep systems running efficiently and protect equipment from wear and damage.

- Stable viscosity across temperatures: The oil should remain fluid enough in cold starts and not thin out excessively under heat. This ensures smooth power transfer and consistent performance.

- Oxidation and thermal stability: A good oil resists breaking down when exposed to oxygen and high operating temperatures. This extends oil life and prevents sludge or varnish build-up.

- Lubricity (anti-wear protection): Proper lubricating properties reduce friction between moving parts, minimizing wear and extending component life. Anti-wear (AW) additives like zinc dialkyldithiophosphate (ZDDP) are often used.

- Corrosion and rust protection: Hydraulic oil should shield metal components from moisture damage, even in humid or outdoor environments.

6. How often should hydraulic oil be changed?

Typically every 2,000–4,000 operating hours, but it depends on system design, usage, and contamination levels. Condition-based monitoring (oil analysis) gives the most accurate answer.

7. What are the signs of contaminated or degraded hydraulic oil?

Hydraulic oil naturally breaks down over time, and contamination is one of the biggest threats to hydraulic systems. Knowing the warning signs helps prevent costly repairs or downtime.

Common signs include:

-

Milky or cloudy appearance: Usually caused by water contamination. Moisture mixes with oil, reducing lubrication and increasing the risk of rust.

-

Dark colour or burnt smell: Indicates oxidation or overheating. Oil has lost its protective qualities and may leave sludge or varnish deposits.

-

Sludge, sediment, or particles: A sign of dirt, metal wear, or additive breakdown. This can clog filters and damage pumps and valves.

-

Excessive foaming or bubbles: Air contamination leads to aeration or cavitation, causing noisy operation, vibration, and poor efficiency.

-

Sluggish or noisy system performance: If machinery runs hotter, moves slower, or makes unusual noises, the hydraulic oil may no longer be protecting the system properly.

👉 Pro Tip: Regular oil analysis and visual checks are the best way to catch problems early. Monitoring oil condition helps extend both fluid and equipment life.

8. Can you mix different hydraulic oils, and what happens if you do?

Mixing is not recommended. Different formulations can react badly, reducing lubrication, harming seals, or creating sludge. Always stick with the same oil type and grade unless a flush and refill is done.

9. What problems can the wrong hydraulic oil cause?

Using the wrong hydraulic oil might seem like a small mistake, but it can create serious system issues over time. Hydraulic systems rely on precise fluid properties to operate correctly, and the wrong oil disrupts that balance.

Key problems include:

-

Increased wear and premature failure: If the oil lacks proper anti-wear additives, moving parts (pumps, valves, cylinders) suffer accelerated friction damage.

-

Overheating and reduced efficiency: An oil with the wrong viscosity (too thick or too thin) causes extra heat, energy loss, and sluggish system performance.

-

Seal and hose damage: Incompatible oils can cause swelling, shrinking, or cracking of seals and hoses, leading to leaks and contamination.

-

Foaming, aeration, or cavitation: Incorrect fluid properties may trap air, which reduces hydraulic power, creates noise, and can pit metal surfaces.

-

Corrosion and sludge formation: Oils without adequate protection may allow rust or encourage sludge build-up, clogging filters and damaging sensitive components.

-

Unexpected downtime and costly repairs: Ultimately, the wrong oil increases maintenance costs and risks catastrophic system failure.

👉 Bottom line: Always use the oil grade and type recommended by the equipment manufacturer. It protects your machinery, keeps it efficient, and saves money in the long run.

10. How should hydraulic oil be stored and disposed of safely?

Hydraulic oil is valuable, but it can become hazardous if mishandled. Safe storage extends its shelf life, while proper disposal protects people, equipment, and the environment.

✅ Storing Hydraulic Oil Safely

-

Keep containers sealed – Prevent dirt, water, and air from contaminating the oil.

-

Store in a clean, dry place – Avoid damp areas, direct sunlight, and extreme temperatures. Heat accelerates oxidation, while cold may cause thickening.

-

Use proper containers – Metal drums or approved plastic containers with tight-fitting lids.

-

Label clearly – Mark oil type and date received to prevent mix-ups.

-

First in, first out (FIFO) – Use older stock before newer stock to avoid degradation during storage.

♻️ Disposing of Hydraulic Oil Safely

-

Never dump it – Pouring oil down drains, into soil, or into water is illegal and harmful.

-

Use approved collection points – Take used oil to licensed recycling or disposal facilities.

-

Consider recycling – Many waste companies filter and re-refine used oil for reuse.

-

Handle responsibly – Wear gloves and avoid skin contact; hydraulic oil may cause irritation.

-

Contain spills immediately – Use absorbent pads or granules and dispose of waste correctly

Why Buy Hydraulic Oil from Flowfit?

- Premium Quality: We supply hydraulic oil made from top-grade materials, ensuring long-lasting durability and exceptional performance in even the most demanding applications.

- Comprehensive Range: We offer a comprehensive range of hydraulic components—including pumps, valves, cylinders, hoses, fittings, and fluid control systems

- Customisable Solutions: Flowfit provides tailored power units that meet the unique specifications of your equipment and industry.

- Free UK Shipping: We offer free UK shipping on orders over £250, making it easier and more affordable to get the hydraulic components you need delivered straight to your door.

- Global Shipping: Flowfit proudly serves customers across the UK and worldwide, ensuring that top-quality hydraulic products are available no matter where you are.

Browse our selection of hydraulic oil and find the ideal hydraulic solution for your needs. Our team of hydraulic specialists are ready to assist you with expert advice and help you find the best products for your equipment.

For more information, get in touch with our team of hydraulic specialists today!

The total one-stop supplier for hydraulic components & systems

Get in touch

Parys Road

Ludlow

Shropshire

SY8 1XY