Improving Safety and Efficiency in Rope Inspection with Hydraulics

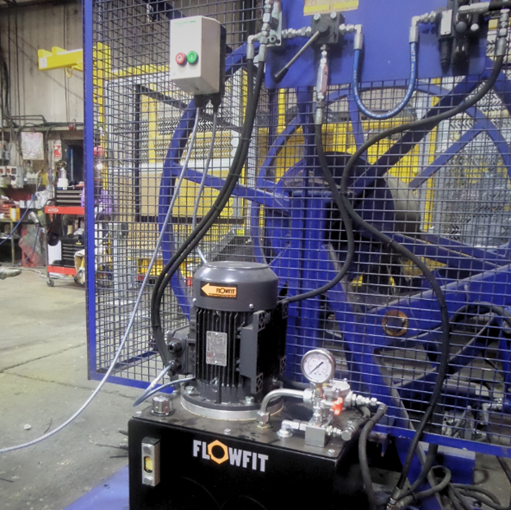

Flowfit partnered with a specialist equipment manufacturer to supply a robust industrial hydraulic power pack for integration into a cable winding machine used during winch-rope inspection and maintenance. This image shows the Flowfit hydraulic power pack installed within the system, providing the essential hydraulic force required for controlled rope handling.

The winding machine is designed to reel off, rewind, and tension heavy-duty cable-hauling ropes, enabling technicians to safely examine rope wear, structural integrity, and overall rope condition throughout the inspection process.

How the System Works

The winding machine is designed to reel off, rewind, and control the tension of heavy-duty winch ropes during inspection procedures. The Flowfit power pack provides the hydraulic force required to operate the machine’s rotating drum and tensioning system.

Role of the Flowfit Hydraulic Power Pack

The installed Flowfit power pack serves as the primary hydraulic power source, delivering consistent pressure and flow to drive the machine.

Key functions of the machine includes

- Hydraulic motor drive: Powers the winding drum responsible for pulling and reeling rope during inspection.

- Tension control: Maintains smooth and adjustable rope tension, enabling technicians to visually examine rope condition, wear, and integrity.

- Smooth rope handling: Ensures controlled spooling to prevent kinks, sharp bends, or sudden load changes that could damage the rope.

Flowfit IPU Power Unit includes

- Electric motor: Drives the hydraulic pump and primary source of power.

- Hydraulic reservoir, manifold block and Pressure gauge:: Houses fluid, filtration, control valves and allows operators to monitor system pressure during operation.

- Hydraulic hoses & fittings: Distribute pressurized fluid to the machine’s drive and tensioning components.

Application Context

These winding systems are commonly used in:

- Winch rope inspection and certification

- Maintenance workshops

- Manufacturing and repair facilities for lifting or pulling equipment

- Safety-critical operations where rope condition must be periodically checked

The combination of the Flowfit power pack and winding machine provides a reliable, controlled, and industrial-strength solution for handling long, heavy ropes during inspection procedures.

Ready to Upgrade Your Hydraulic Systems?

Interested in finding the right power unit for your application? View our full industrial range.

For advice or a custom-built system, get in touch and let our engineers help bring your project to life.

The total one-stop supplier for hydraulic components & systems

Get in touch

Parys Road

Ludlow

Shropshire

SY8 1XY